Integrated Management System

Effective IMS for Holistic Quality

Product quality is the focus of quality processes, as the expectations placed on products and the associated requirements for product manufacturing are diverse. In this context, customers usually expect a Quality Management System that must be certified to ISO 9001 or IATF 16949, for example. In addition to the obligation to comply with legal requirements, companies are also increasingly required to meet other management system standards – for example for the environment, occupational safety or IT security. No matter which requirements you have to meet: we offer you the right software support.

Quality Assurance (QA) and Quality Management (QM)

By applying proven QA and QM methods, you continuously check and improve the quality of your products and processes and meet quality requirements.

Quality Management System (QMS)

The QMS is the part of your management system that deals with "quality". With the certification of your QMS, you provide formal proof that the required normative (minimum) requirements for a QMS, e.g. from ISO 9001, IATF 16949 or ISO 13485, are fulfilled.

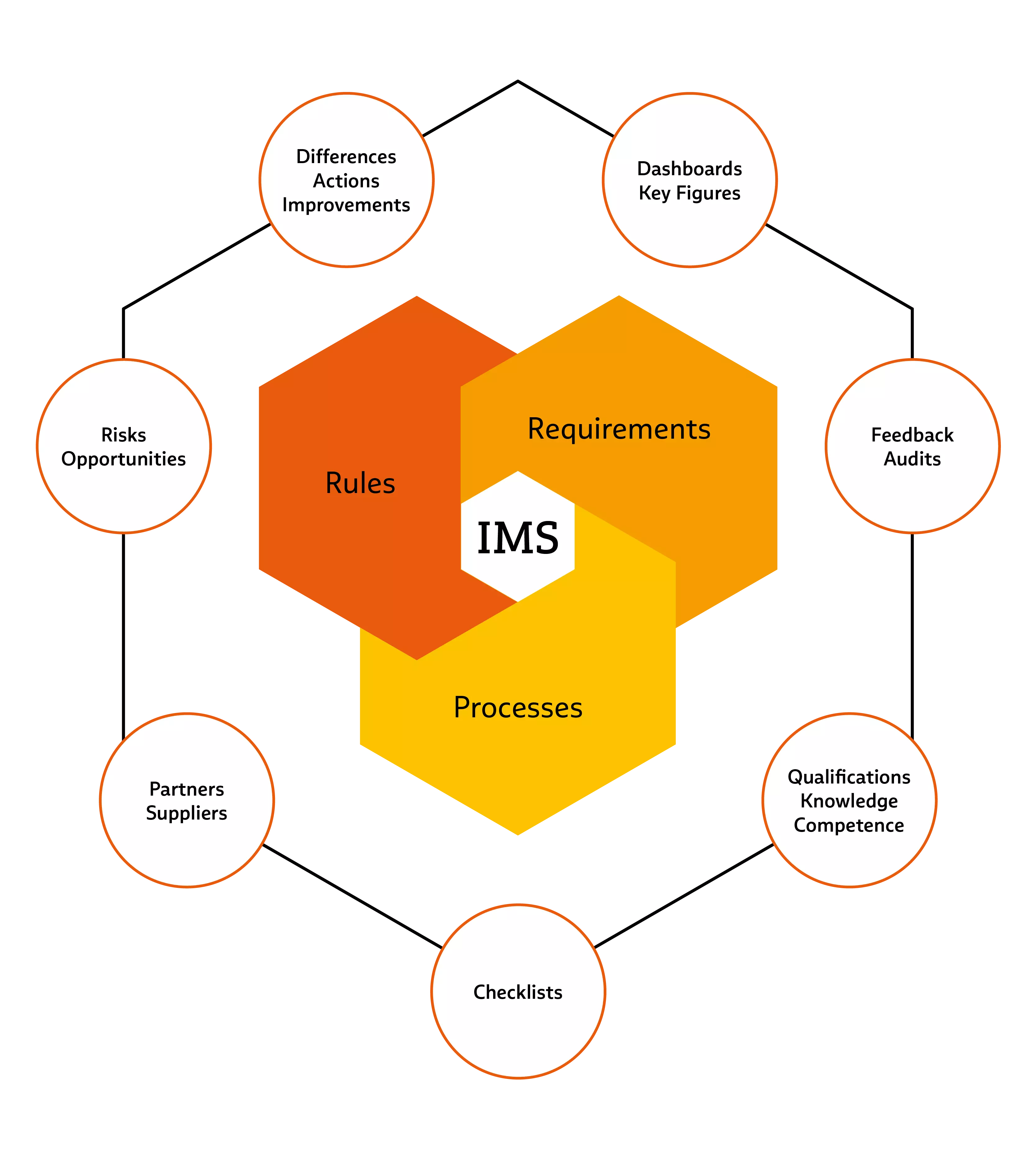

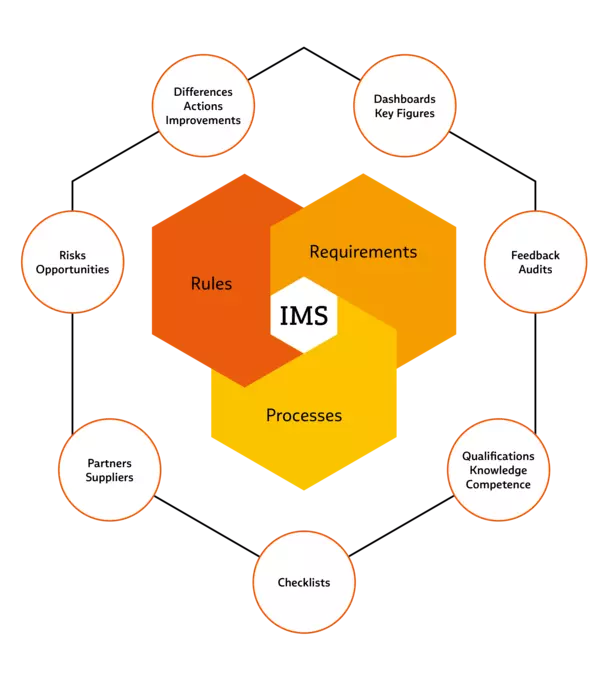

Integrated Management System (IMS)

By additionally considering the requirements of other management system standards in the context of your management system, it is easier to identify identical or similar requirements when implementing them, recognize synergies and thus reduce costs.

On the Way to an Integrated Management System

The various management system standards result in many requirements for the IMS

Your Quality Management System (QMS) focuses on the quality processes that ensure that your product development and manufacturing processes meet your customers' requirements and deliver flawless products. However, good quality management means continuously developing your QMS and making it effective – not least because of the ever-changing requirements and challenges that arise in your company's environment and on the market. Considering your QMS as part of an Integrated Management System (IMS) that also takes into account environmental, IT and occupational safety or sustainability requirements, especially against this background, helps to ensure that quality is created in every respect and that your company can be successful in the long term as well as sustainably.

In practice, however, the requirements from the various management system standards or from laws and official regulations are often dealt with by the respective department heads (for quality, environment, IT, etc.). The same or similar requirements are often checked and analyzed several times and ultimately fulfilled with department-specific actions. In addition, various software tools are used to manage the requirements, if they are used at all.

However, if quality is to be achieved in every respect, only one thing makes sense: all requirements that are relevant to your company should be documented in a central location, evaluated together with the specialist departments and taken into account in your (Integrated) Management System. To do this, you need to analyze which requirements are relevant for which business processes and, in particular, what risk could be associated with a requirement. In order to fulfill requirements, you need guidelines and sensible rules that all employees must know and apply when carrying out their activities. Important prerequisites for this are process descriptions, specification documents and checklists that are easy to understand and accessible at all times, which provide people with security, guidance and support. Because the focus is on people: quality concerns EVERYONE.

Making a management system effective is in the interest of top management and can only succeed through the appropriate process organization of the company in conjunction with motivated and qualified employees. Qualification, knowledge and competence are just as essential as target group-oriented communication – both internally and with your business partners. Using key figures to action successes and failures, dealing with deviations, recognizing risks at an early stage and taking advantage of opportunities, constantly obtaining feedback and continuously implementing improvement actions – all this has long been part of everyday business life, generates quality in every respect and makes up your management system.

How Our Software Solutions Support You

Integration: Modules that help your company to make your IMS effective

Whether QMS or IMS – suitable software tools from Babtec support you in further developing your management system and making it effective.

All requirements relevant to your company are brought together centrally in the “Requirements Management” module, providing your specialist departments with a common platform for exchanging information on (new) requirements, making decisions and involving process owners in order to define and implement suitable rules for fulfilling the requirements.

The “Process Management” module contains the documented process map with all core, management and support processes as a guide through your process organization. This is where you describe all processes and activities – clearly laid out, easy to understand and including all valid documents with detailed specifications and rules.

With the "Checklists" module, you can guide your employees in carrying out their activities and help them to internalize guidelines and rules in practice. Use the handy "Qualifications Matrix" to ensure that everyone involved has the necessary qualifications and skills for their role. This allows you to easily and reliably identify training requirements and plan the necessary training and further education actions.

The "Risk Management" module supports you in taking a holistic view of all business risks and opportunities in the context of your management system; because recognizing risks at an early stage, but also being aware of opportunities and seizing them, is part of everyday business today.

Last but not least, as the person responsible for the process, you can use early warning indicators and key figures in the "Quality Cockpit" module to monitor the effectiveness of your processes, identify deviations at an early stage and initiate improvement actions. You can track all actions, tasks and deadlines in the central Task and Action Management.

Let's Talk to Each Other

Would you like more information about our products, perhaps even in a personal consultation? Then please feel free to contact us!

You can reach us at the following times:

Monday–Thursday, 9:00 a.m.–4:00 p.m.

Friday, 9:00 a.m.–1:00 p.m.