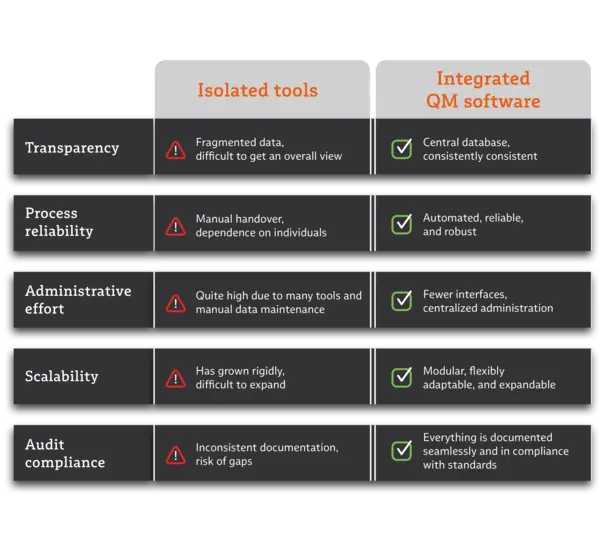

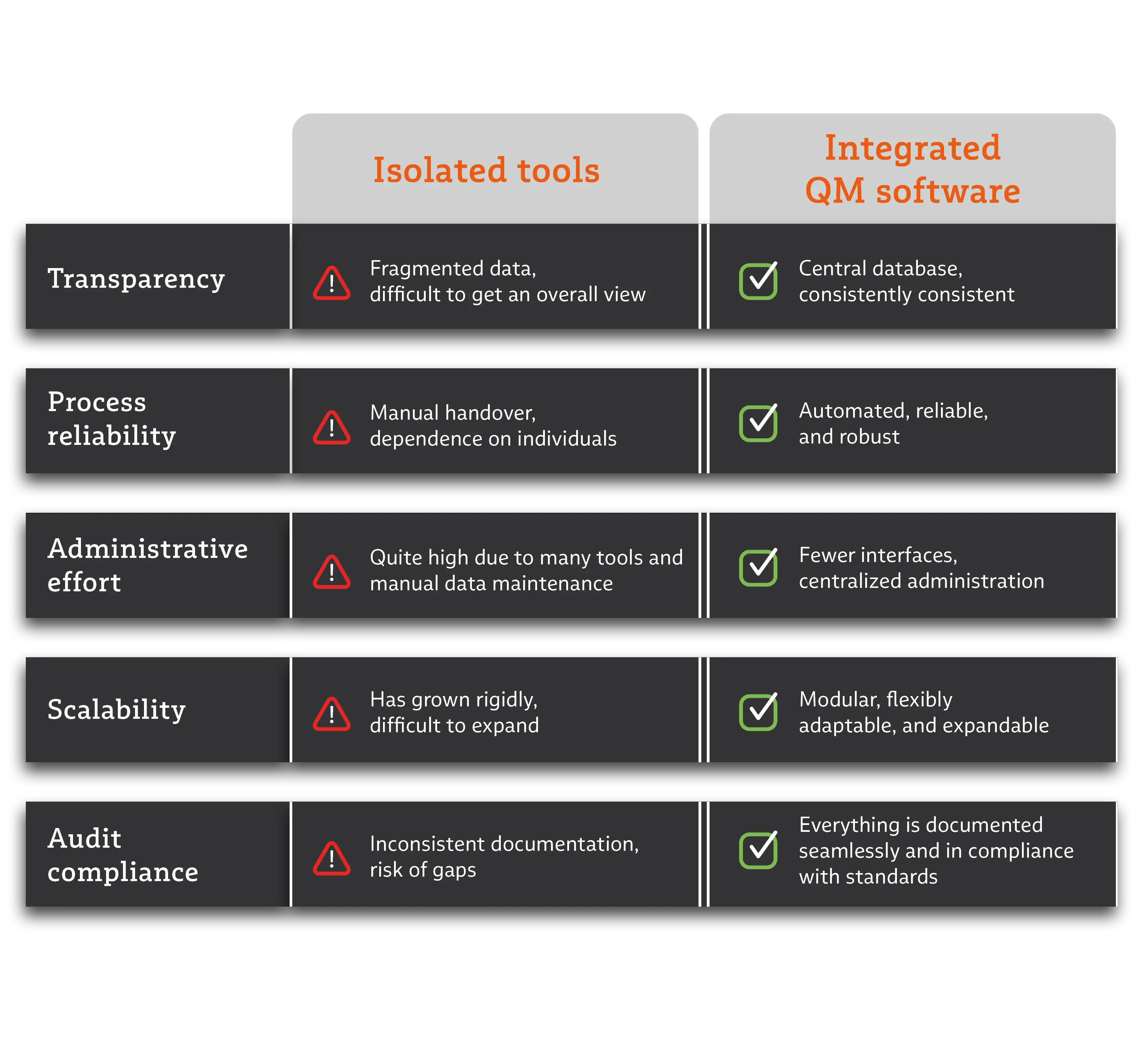

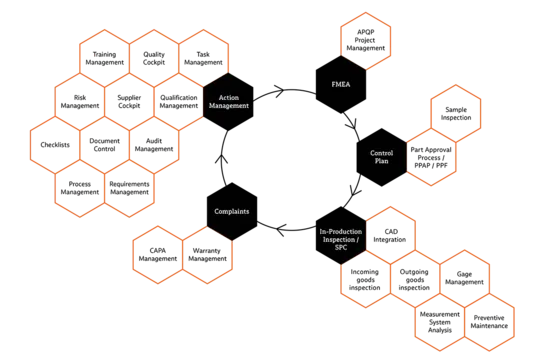

The result: important quality data is scattered across various software solutions, Excel spreadsheets and emails. This leads to duplicate data storage and often breaks in the process between different, incompatible formats. Manual data transfer also increases the effort involved and the likelihood of errors or incomplete information. Overall, such a patchwork of isolated solutions hinders the flow of information and makes it difficult to maintain a consistent view of quality-related processes.

An integrated QM solution is the alternative to such isolated software systems. Instead of numerous individual solutions connected by interfaces, it brings together all quality-related processes, data and documents in a central location. This creates transparency, reduces complexity and saves time. As a result, there are numerous advantages:

Comments

No comments